As part of its hydrogen strategy, RWE has ordered a 10 MW pressurized alkaline electrolyzer from Sunfire. The plant for producing green hydrogen is planned to be installed in Lingen in 2022. For Sunfire, the contract signing marks a new era in the company’s business development.

Lingen, May 3, 2022 | With its new “Growing Green” strategy, energy utility RWE is planning extensive investment in sustainable technologies. By 2030, the company aims to build at least 2 GW of electrolysis capacity to produce green hydrogen.

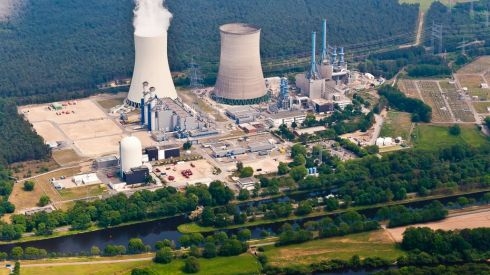

Part of the strategy: a 14 MW pilot plant with two different electrolysis technologies at the Lingen site. For the pressurized alkaline electrolyzer, RWE is choosing Sunfire, one of the world’s leading electrolysis companies. The 10 MW plant will produce green hydrogen under industrial conditions using renewable energy.

“We are looking forward to working with another renowned industrial company,” says CEO Nils Aldag. “Our partners like RWE are facing enormous decarbonization challenges. They need fast solutions that give them long-term planning security. We at Sunfire meet these requirements with our pressurized alkaline electrolyzers.”

For Nils Aldag, signing the contract marks the beginning of a joint learning process: “During the construction of the first industrial electrolysis plants, all parties involved will gain valuable experiences,” the Sunfire CEO states. “We as an electrolysis company will benefit from this just as much as our industrial partners who want to cut fossil fuels in the long term.”

With the acquisition of the Swiss electrolysis company IHT early 2021, Sunfire has established a unique product portfolio. While the innovative SOEC high-temperature electrolysis technology – for which Sunfire is well known – is undergoing a final development stage, the Dresden-based company is already meeting the enormous demand for electrolysis capacity with its proven pressurized alkaline electrolyzers.

Sunfire has optimized the alkaline technology, which has been demonstrated in industrial projects around the globe for decades. The company is currently planning to expand production capacities to 500 MW/year by 2023. The RWE pilot project marks just the start of Sunfire’s large-scale electrolysis business. Another 20 MW project with the Finnish power-to-X pioneer P2X Solutions is already being planned.

Image: © RWE

Sunfire is a global leader in the production of industrial electrolyzers based on pressurized alkaline and solid oxide (SOEC) technologies. With its electrolysis solutions, Sunfire is addressing a key challenge of today’s energy system: Providing renewable hydrogen and syngas as climate-neutral substitutes for fossil energy. Sunfire’s innovative and proven electrolysis technology enables the transformation of carbon-intensive industries that are currently dependent on fossil-based oil, gas, or coal. The company employs more than 650 people located in Germany and Switzerland.

For more information visit www.sunfire.de