Rotterdam, 24 May 2019.

This Friday May 24, Rotterdam The Hague Airport and a European consortium led by EDL Anlagenbau Gesellschaft mbH will sign a cooperation agreement for a study, which aims at developing a demonstration plant that produces renewable jet fuel from air. This plant aims to be the first worldwide to offer renewable jet fuel from air to the market. Compared to conventional fossil-based jet fuels, renewable jet fuel from air has a significantly lower carbon footprint and fine particles emission. This project thus demonstrates a significant step towards a carbon-neutral aviation industry.

Sustainable Aviation

The aviation industry is an emitter of carbon dioxide (CO2) and air travel continues to increase. This also applies to Rotterdam The Hague Airport, where the number of passengers keeps growing every year. Unlike cars, airplanes cannot switch to electric or hydrogen propulsion in the short-term. Rotterdam The Hague Airport is therefore proud to kick-start the realization and commissioning of this plant for the production of renewable jet fuel from air.

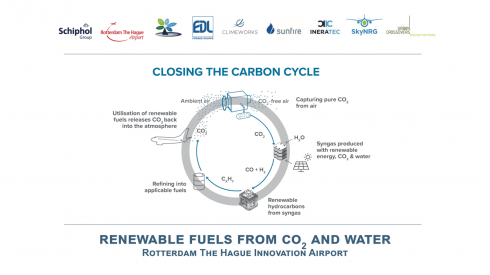

The path towards production of renewable jet fuel from air

Following the study, a demonstration plant is to be realized and commissioned on the premises of the airport, producing about 1’000 liters of renewable jet fuel per day. This would be the first time ever that renewable jet fuel from air production exceeds laboratory scale of a few liters per day. A series of highly innovative, but proven technologies are linked to each other to achieve this: First, CO2 is captured from ambient air by Climeworks’ direct air capture technology. The gas is subsequently transformed into syngas through electrolysis, using electrolyser cells developed by Sunfire. Then, the syngas is turned into synthetic hydrocarbons by means of Fischer-Tropsch synthesis, enabled by Ineratec. Finally, EDL takes care of the process to convert synthetic hydrocarbons into jet fuel and of the overall process and plant integration. The entire process runs sustainably, thanks to renewable energy, preferably produced on site from the airport’s solar panels.

SkyNRG, the global market leader for sustainable aviation Fuel solutions, is in this project responsible for the commercialization strategy.

The first potential customer has also announced itself. Transavia has committed itself to the plan and indicated it intends to reduce its CO2 exhaust with renewable fuel from air in the future.

Innovation Campus

Due to the innovative technologies that will be applied the demonstration plant will be relatively compact. The architectural integration by Rotterdam based Urban Crossovers & Blueroom will ensure that the plant is part of the overall RHIA campus and fit in both its size and in its objectives.

Foundation Rotterdam The Hague Innovation Airport

The set-up of this plant is facilitated by the foundation Rotterdam The Hague Innovation Airport (RHIA), which was established by the airport and the City of Rotterdam. The foundation focuses on promoting four issues – Entrepreneurship, Energy & Environment, Education, and Emergency – through several innovative projects. The study on renewable jet fuel from air is the first of these projects.

Goal of the study

The study will define the concept and basic engineering for onsite production of renewable jet fuel from air at Rotterdam The Hague Airport. It will enable a cost estimate for both the actual construction of the plant and the fuel itself, which will be decisive for further project development. Rotterdam The Hague Airport is an ideal location for the study due to its size and organization. Royal Schiphol Group, the parent company of RTHA, through its Schiphol Innovation Board, is a partner in making this project possible.

Future

The large-scale production of renewable jet fuel requires an upscaling and, where beneficial, an integration into existing refineries, which will not take place at the airport. Instead, this project aims to provide one of the keys to the transformation of the current fossil dominated petrochemical complex of the Rotterdam Harbor. However, smaller renewable jet fuel production facilities can also be attractive to utilize stranded decentralized renewable power and for remote consumers.

Sunfire is a global leader in the production of industrial electrolyzers based on pressurized alkaline and solid oxide (SOEC) technologies. With its electrolysis solutions, Sunfire is addressing a key challenge of today’s energy system: Providing renewable hydrogen and syngas as climate-neutral substitutes for fossil energy. Sunfire’s innovative and proven electrolysis technology enables the transformation of carbon-intensive industries that are currently dependent on fossil-based oil, gas, or coal. The company employs more than 650 people located in Germany and Switzerland.

For more information visit www.sunfire.de